Battery Technologies & Mini Battery Samples

Battery Technologies & Mini Battery Samples

Today, we learned current battery technologies at the factory. The battery is a device that converts chemical energy into electric energy multiple times through an electrochemical oxidation-reduction (redox) reaction. This type of reaction involves the transfer of electrons from one material to another. My director challenged me by asking what the differences between the battery and cell battery. In understanding the differences between a cell and a battery, one should think of a battery as one or more of these cells connected in series, or parallel, or both, depending on the desired output voltage and capacity. Then, another professional from the department of the new technologies explained to me the technologies of battery that is used at the factory.

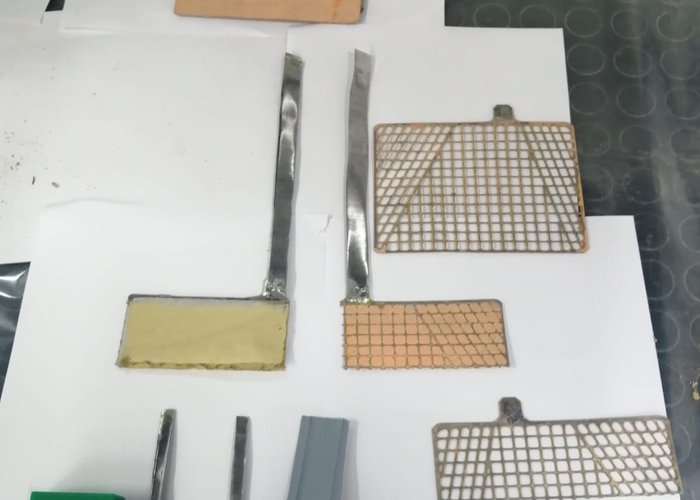

At the research and development center, we also involved a research project to make quality and capacity tests without doing the whole battery. The aim was to make the battery just from a couple of plates. Also, plates were dividing into pieces with saving the battery terminals. In this way, the lead is used in battery samples was reduced. It was trying to show that it can be visualized or predicted the expected results from the mini sample batteries. We were testing positive plates, that's why it was used a single positive plate in the separator and two negative plates. Here, there was an excessive negative plate to see the results in the positive plate. Glassfiber was used as a separator. Plates were covered by a separator to prevent short circuit, also we made the brazing with considering the possible short circuits between the small plates. In the corrosion test, it's important to consider the surface area. Therefore, the tests and simulations for charging and discharging were made by consideration in this matter.

If brazing made to the battery terminals wrongly, the battery terminals get shorted in the cell box. Before the brazing, the battery terminals were fluxed with a surface remover in order to make the brazing stronger. The lead was used in the plates. The cell box was made from poles that polyethylene 1000 and endurable to the strong acids. 150 ml of sodium sulfate was put to the cell box. It was observed that the reaction was started and the box was getting warm due to the exothermic reaction. In the regular band process, first, diluted acid then the regular acid is put to the cells due to the increase in heat. We covered the top of the cell with paraffin, air release was not checkable like in the regular battery cap. The air release from the battery was ignored. The cell was started to charge with the battery testing system and it was arranged to the multiple times' charge and discharge loop by a simulation. The system records battery data like capacity or volt every 600 sec. And it set to 50 energy cycles. The mini battery should have shown 2 Volt and it refers that it had has enough active matter on it, there was no pouring on the plates and the experiment was successful.

-

Aug. 8, 2019

by Zuhal Cakir