Piezoelectric Materials

Piezoelectric Materials

Piezoelectricity, which is a field in crystal material science, was started by the brothers Jacques Curie and Pierre Curie in 1880. They found a special characteristic of certain crystalline minerals like tourmaline, quartz, topaz, cane sugar, and Rochelle salt. It was found that pressure and compression created voltages of inverse polarity and corresponding to the connected stack. This was called by Hankel, the piezoelectric impact. The word piezoelectricity comes from Greek and implies power coming about from pressure. This likely makes piezoelectric materials the oldest type of smart material. Next year, Lippman anticipated the presence of the converse impact basing on essential thermodynamic standards. At the end of 1881, the brother Curies affirmed experimentally the presence of the converse impact. They appeared that in the event that one of the voltages generating crystals was uncovered to an electric field it stretched or abbreviated concurring to the polarity.

The first application of the piezoelectric impact was an ultrasonic submarine locator created with World War 1. A mosaic of lean quartz crystals stuck between two steel plates acted as a transducer at 50MHz. By submerging the device and applying a voltage they succeeded in emanating a high frequency 'chirp' submerged, which empowered them to measure the profundity by timing the return echo. This was the premise for sonar and the advancement encouraged other applications utilizing piezoelectric devices both resounding and non-resonating such as receivers, flag channels, and ultrasonic transducers. But, numerous devices were not commercially practical due to the restricted performance of the materials at the time.

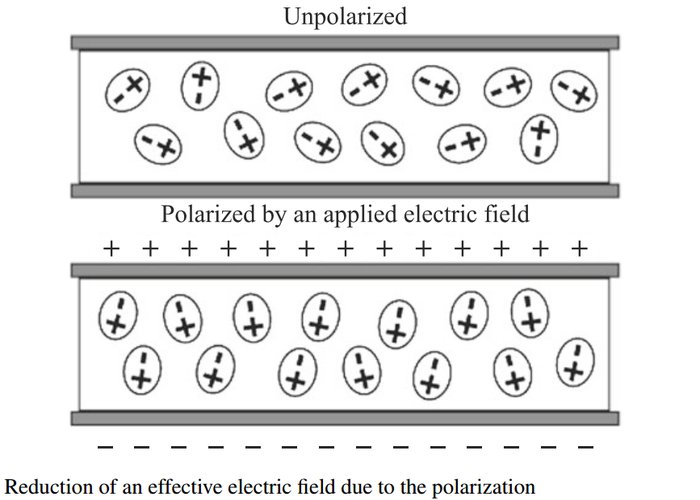

When we look up to the technical properties of the piezoelectric materials, that can be seen that piezoelectric materials are ionically bonded. There are atoms with positive and negative charges. Ions in the piezoelectric material generate particular repeating unit cells. There will be a net movement of the oppositely charged ions if a unit cell is nonsymmetric. Herewith, electric dipole or polarization present in the structure of piezoelectric materials. Especially, the dipoles that occur because of the nonsymmetric structure, gather with their neighbors to the same array. These dipoles also form domains. When piezoelectric fibers are generated, randomly directed domains are nonpolarized and therefore there is no piezoelectric impact in the first statement. Performing heat or strong DC field cause that the domains to get into line. After the temperature is decreased and the DC field is moved away, the domains conserve their steady. Eventually, an overall line is produced and the material is piezoelectric. There are some influencing factors of a degree of piezoelectricity. If performed tensile or compressive stresses are changed, the degree of polarization will affect.

The most commonly used piezoelectric ceramic today is lead zirconium titanate (PZT). By changing the material chemistry, the physical properties of PZT could be controlled. There are some problems with PZT that is attaching it to other materials. Also, there are restrictions related to PZT; it is brittle and has a lack of mechanical durability like all ceramics. When we look at the application of the piezoelectric effect, piezoelectric materials are implicit in actuators in the semiconductor industry, in the microscopic cell handling system in the microbiology field, in inkjet printers where motion control is essential, and in fiber optics and acoustics. Moreover, the piezoelectric materials could be used in sensors that produce an electrical field for reaction to a mechanical impulse. It ensures many advantages in buildings with damping systems and earthquake detection systems. However, it is the most famous in sensors that supply deploying car airbags when necessary. When the material is affected by the pressure from a car crash, it generates an electric field that allows to deploys the airbag.

More recently, there can be seen innovations with the help of piezoelectric technology in the sports industry. For instance, smart skies are designed to carry out both soft and hard surfaces in favor of piezoelectric applications. Also, at the beginning of the tennis equipment, rackets had to be designed to be stiff in order to make high speed with the ball. However, it implies that racket transfers the shock vibration to the tennis player’s arm. It causes risky injuries.

In an endeavor to diminish vibration, piezoelectric fibers have been inserted into the racket throat and a computer chip implanted to the handle. The framework avoids when the ball is hit so that the piezoelectric fibers twist and create a charge that is collected by the designed electrode surrounding the fibers. The charge and related current are carried to inserted silicon chip through a circuit containing inductors capacitors and resistors, which boost the current and send it back to the fibers out of phase to decrease the vibration on the racket. As a result, the fibers bend to the opposite motion of the racket and succeed in decreasing the rate of injuries. The manufacturers assert that a 50% reduction in vibration contrary to earlier rackets.

References

Books:

1. P.S. Dineva, D. Gross, R. Müller, T. Rangelov, Dynamic Fracture of Piezoelectric Materials, Springer International Publishing Switzerland, 2nd edition, 2014.

2. N. D. R. Goddard, R. M. J. Kemp, R. Lane, An overview of Smart Technology, Packaging Technology and Science, Volume 10, pp 129–143, 1997.

Websites:

3. Dr. Irene Turner, "Piezoelectric Materials and Applications”, http://classroom.materials.ac.uk/casePiez.php, 2010.

-

May 12, 2017

by Zuhal Cakir